|

|

Food and beverage labels: trendy gameplay vs. printing magic, four highlights take you flying!With the rapid development of lifestyle Food and beverage packaging is also constantly iterating and upgrading Keeping pace with the times to meet people's needs So, in this era full of vitality and innovation What new trends and tendencies have emerged in the label design of food and beverage packaging? What kind of label design can become an excellent "salesperson" for a product Create a unique "business card" for the product? Let's take a look together Innovative and outstanding labels not only express and present artistic craftsmanship, but also showcase a wonderful sensory feast; And can provide targeted and customized solutions to meet the needs of customers, conveying a dual exquisite texture of visual and tactile senses. Recently, Rangcha Zhuxiang Oolong has received a packaging upgrade, adding a cute Panda Baby "Rangrang" sticker on top of the original bottle label. The illustration of "Rangrang" panda was created by renowned painter and illustrator Ouyang Pengjie, with bamboo fragrance paired with pandas to cater to the young consumers' pursuit of "bamboo" and "panda" Chinese style elements. It provides consumers with a comprehensive product experience of bamboo forest tea fragrance from the perspectives of smell, taste, and vision.

The focus of Low Spread brand building is to convey the advantages of the product through its name and attractive visual effects, thereby resonating with consumers who value health and trends. The visual image of this label design does not rely on traditional fruit images, but uses eye-catching and intuitive numbers to emphasize the calorie content of the product. This concise and bold layout brings a powerful and honest image, ensuring that the brand name and packaging information stand out.

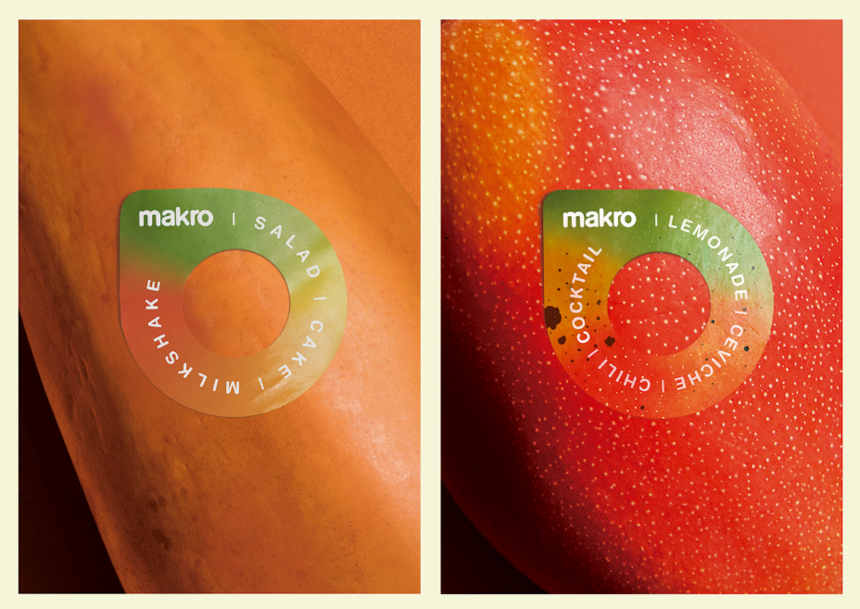

In the food industry, many labels need to be directly attached to the surface of the food rather than the packaging, so there are higher requirements for the safety of label materials and adhesives. Labels can help solve the two major issues of security and anti-counterfeiting, playing an important role in providing customers with peace of mind and improving product integrity. The Amcor SmartTack tamper proof tag adopts a proprietary tag design and has excellent tamper proof capabilities. By clearly indicating whether the packaging has been opened from areas other than the peeling label, the safety of the packaging can be enhanced. This technology always includes the starting point of tearing around the edge of the label, so opening the package from any position other than peeling off the label can provide clear evidence of tampering for consumers and retailers. Makro vegetable and fruit stickers look similar to traditional fruit stickers, but use a color coding system to convey the maturity of fruits and vegetables, mimicking their colors at different stages with labels. The colors on the label correspond to different food or cooking suggestions. For example, banana stickers range from green, yellow, brown, to black, corresponding to Fried, Ice cream, Tempura, and Cupcake, respectively. Green bananas are suitable for deep frying; Yellow can be made into ice cream; And if the brown color is slightly soft, you can try making it into banana tempura; Bananas with black spots are very suitable for making cupcakes because their sweetness increases. Other fruits, such as blackened avocados, can be used to make sauces, while ripe mangoes can be used to make cocktails By sticking small stickers on fruits and vegetables, these "leftover foods" that were abandoned by consumers just because of their appearance also gained a brief "rebirth"

In recent years, consumers have become increasingly aware of the significance of sustainable packaging, and brands are better meeting customers' future needs through sustainability labels. NatureTag is designed specifically for fresh agricultural products, and these tags match the rate of decomposition of food skin, completely degrading into compost within 365 days, truly achieving a return to nature. Whether it's bananas, avocados, cabbage, or celery, NatureTag can safely fit and fully comply with EU regulations. Its pressure-sensitive adhesive 114 component is safe and reliable, and can firmly adhere even at room temperature. After use, it can be easily removed without leaving any traces. This is a revolutionary eco-friendly product that is not only environmentally friendly, but also brings practical economic benefits to agricultural growers and supply chains. Similarly, if the product is accidentally discarded, the label will not cause any damage to the ecology and wildlife. Recently, the North American company (FSA) of the Faurecia Adhesive Division launched a new compostable adhesive semi gloss label paper, which has obtained industrial composting certification. Recently, the North American company (FSA) of the Faurecia Adhesive Division launched a new compostable adhesive semi gloss label paper, which has obtained industrial composting certification. The label material is combined with CP1 acrylic adhesive, which enables the entire packaging, including the label, to be processed through industrial composting processes without any risk of environmental pollution. With the rapid development of online shopping at a speed unimaginable a few years ago, brands are rethinking how to handle packaging and products. With the support of internet technology, packaging has taken on more new roles, extending consumers' purchasing experience beyond the packaging itself and achieving a good extension, thereby increasing consumers' real experience of enjoying products. For example, QR code tags can provide consumers with more information beyond the content of the tag, tell more persuasive brand stories, and satisfy consumers' thirst for product knowledge and information; Electronic tags can also be embedded in packaging, allowing consumers to experience beyond the real world through the use of augmented reality (AR) technology. Meanwhile, smart tags also provide more possibilities for anti-counterfeiting traceability and sustainable packaging of products. Provide detailed information on the operation of the product production line, the packaging lifecycle and sources, including its production methods and how it can be reused or recycled. These safety and environmental issues that consumers are increasingly concerned about and concerned about can be addressed through smart labels. These detailed information will undoubtedly deepen the connection between consumers and brands, thereby establishing long-term loyalty with the brand. On the occasion of the 51st World Environment Day, Dongpeng Beverage Group announced that the classic bottle of Dongpeng Special Drink will launch an "environmentally friendly version": "tear off" the physical label and replace it with electronic labels. Consumers can scan the "unlabeled" version of Dongpeng Special Drink and stamp it with a QR code. The product's raw materials, efficacy, specifications, production date, batch, manufacturer, and other information are clear at a glance, and they can also receive the honorary title of "Low Carbon Striver" issued by Dongpeng Special Drink. The brand and consumers can directly communicate, and the interaction is stronger. After tearing off the physical label, there is no fear of not being able to identify Dongpeng Special Drink products. On the occasion of Jones Soda's 25th anniversary, the company relies on content creators to elevate its label to a new level, namely augmented reality (AR). The company stated that it has launched a series of limited edition AR bottle labels showcasing the activities of 15 extreme athletes and avant-garde artists. Jones' five best-selling soda flavors all use AR labels, and a total of 1.5 million bottles were produced throughout the event. Consumers can activate these tags through a new smartphone application developed by Jones Soda in collaboration with marketing agency Triggerhouse. After downloading the Jones dedicated application, consumers can use their smartphone camera to scan images on any Jones soda bottle with the Reel Label icon. The scan triggered a short video that takes the audience into the unique world of its creator, whether he or she is painting a mural, falling into a skateboard bowl, or doing a hard flip in a skateboard park. As is well known, food packaging has extremely high safety requirements for packaging materials, and labeling is no exception. So, how can we ensure the safety of food labels? Adhesive labels used for food packaging are mainly divided into two categories: one is labels that come into direct contact with food, such as fruit labels; The second is labels that come into indirect contact with food, such as labels attached to food packaging boxes. Relatively speaking, the safety requirements for labels that come into direct contact with food are relatively high, generally requiring materials to comply with FDA certification in the United States; The labeling requirements for indirect contact with food are relatively low, as long as they comply with national standards. At present, the most commonly used adhesive labels in the market are those that come into indirect contact with food. What kind of materials can be used for food labeling, whether in direct or indirect contact? Generally speaking, it can be classified according to the different surface materials and adhesives of the adhesive. Adhesive materials can be divided into paper and film materials according to different surface materials. Among them, most of the adhesive materials for paper-based surface materials can be used to make food labels, while the adhesive materials for film based surface materials are mainly divided into PE, PP, PET, and other special films. PE and PP materials are non-toxic and can be used to process food labels, while the non drying adhesive materials for other film based surface materials need to determine whether they can be used to process food labels based on their own properties. In practical applications, thin film adhesive label materials are mainly used for non direct contact food packaging. Adhesive materials can be divided into three categories based on the type of adhesive: water-based adhesive, hot melt adhesive, and solvent adhesive. Among them, water-soluble and hot melt adhesive materials can be used for food labels, while solvent adhesives do not meet the requirements for food materials due to their inherent toxicity. In practical applications, water-based adhesive stickers are widely used in combination with paper and film surface materials. However, hot melt adhesive materials, due to their strong fluidity, are prone to overflow during processing. Therefore, they are widely used in combination with paper surface materials to make adhesive stickers, and relatively less in combination with film surface materials. In addition, food labels can be divided into two categories based on the storage environment: refrigerated storage and room temperature storage, and the corresponding adhesive materials for these two types of labels are different. The labeling requirements for food stored at room temperature are relatively low, and only need to meet the labeling needs at room temperature. Currently, the vast majority of adhesive materials on the market can meet the requirements. The labeling requirements for food stored in refrigeration are relatively high, with most requiring labeling and storage in low-temperature environments. This places high demands on the viscosity of adhesive label materials: on the one hand, the viscosity of adhesive materials in low-temperature environments will decrease due to temperature effects; On the other hand, storing at low temperatures after labeling is also not conducive to the adhesion of the label. Therefore, for some foods that require labeling and storage in low-temperature environments, it is recommended to use adhesive labels made of specialized low-temperature glue. Adhesive materials are composed of three parts: surface material, glue, and base paper. Different combinations can make different types of adhesive materials, but no matter how they are changed, the adhesive materials used to make food labels must comply with national standards or FDA certification standards in the United States. Many food labels require printing, and commonly used inks contain large amounts of organic solvents such as toluene and xylene, as well as pigments that may contain heavy metals. Therefore, choosing the appropriate ink for printing food labels is very important. At present, mainstream printing inks are divided into water-based inks, UV inks, and solvent inks. Among them, water-based ink is almost non-toxic and does not contain heavy metal substances, making it the most suitable for food label printing; UV ink also contains relatively low levels of harmful substances. Most UV inks can be detected by SIS and are mostly used for indirect contact with food packaging; Solvent ink does not meet the safety requirements of food labels due to the need for solvents as carriers. However, solvent ink has fast printing speed and low cost, making it particularly suitable for printing large quantities of food packaging. In practical life, many food packaging is printed with solvent ink because the outer layer of the printed packaging and the inner layer in contact with the food will have an inner lining to separate the food from the outer layer, which meets the requirements of food packaging. It is worth noting that regardless of the type of ink, the quality will vary greatly. Therefore, ink suppliers used for printing food labels must provide corresponding test reports and certification materials to prove that the ink meets relevant food printing standards. At present, the implementation standard for food label printing ink in China is the "GB 9685-2008 Hygiene Standard for the Use of Additives in Food Containers and Packaging Materials". Processing environment The traditional adhesive printing process mainly uses relief printing and flexographic printing, which mainly use UV ink and water-based ink printing. They can be used to make food labels, but due to the high hygiene requirements of food labels, the processing environment for food labels is also more stringent. Generally speaking, food label printing requires maintaining workshop hygiene. Before entering the workshop, workshop operators need to change into specialized work clothes and shoes. When entering and leaving the workshop, they need to go through wind forest dust removal to avoid contamination of food labels by external dust. In addition, there are many details that need to be paid extra attention to during the production process of food label printing. The adhesive raw materials used for producing food labels must have complete packaging and cannot be exposed to air halfway before printing. Unused raw materials need to be wrapped in plastic bags or shrink wrap and cannot be directly exposed to the air; During the production process, semi-finished products cannot be directly placed on the ground. They should be placed on clean cardboard. It is strongly recommended to use plastic cardboard because it is cleaner than wooden cardboard, less likely to produce dust, and more conducive to keeping the label semi-finished products clean. The food label production workshop should be regularly cleaned and organized. The workshop should strictly follow the relevant standards to control the "5S" management on site, keep the site clean and tidy, and maintain a certain humidity. It is recommended to control the humidity in the workshop at 50% to 60%. This humidity environment can effectively suppress dust and eliminate static electricity. Otherwise, if there is a lot of dust and static electricity in the workshop, it is easy for the dust to be electrostatically adsorbed on the surface of printed or semi-finished products, thereby contaminating food labels. After producing finished food labels, the packaging process is also crucial. The packaging environment for food labels should be clean and free of static electricity. Finished products should be packaged automatically as much as possible to reduce secondary pollution caused by manual labor. It is recommended that printing companies open a separate workshop with high cleanliness to package food labels. Printing equipment The impact of different printing equipment on food labels varies. Some devices are limited by their own design and are prone to contaminating food labels during the production process, such as the early slanted back trademark machine. This type of equipment has ink that is particularly prone to sticking to the surface of the label during the production process, which can contaminate the food label if it is printed. For example, some polishing equipment may have poor sealing of the ink fountain during the polishing process, which can easily cause the polishing oil to drip onto the surface of the material and contaminate food labels. Compared to inclined back trademark machines, fully rotating automatic label printing equipment is more suitable for processing food labels. This type of equipment is highly automated, and materials run continuously on the equipment |